Features

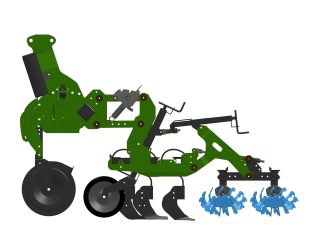

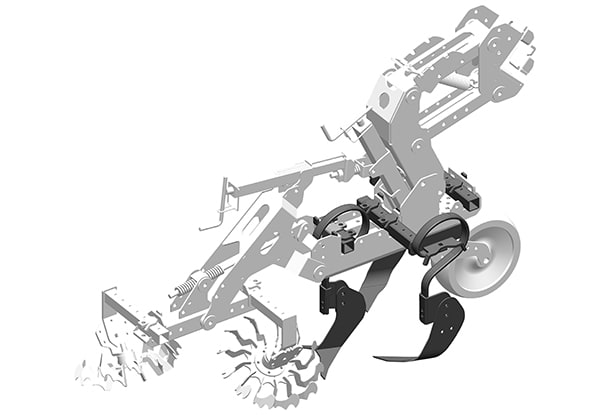

Biotracker is born from the combination of Biosarchio and Tracker.

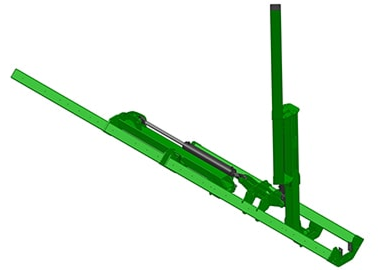

The guidance system has been designed to integrate completely with the cultivator, without adding to the longitudinal dimensions. The machine length has remained virtually unchanged and compact to allow the use of lightweight tractors to avoid excessive soil compaction.

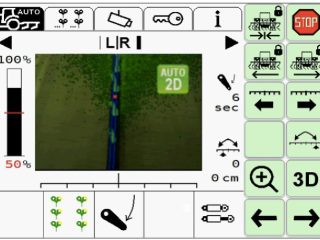

Biotracker allows automatic guidance of the machine between crop rows up to 20km/h. This guidance system reduces operator stress and increases precision and working speed, enabling increased production.

Technical

components

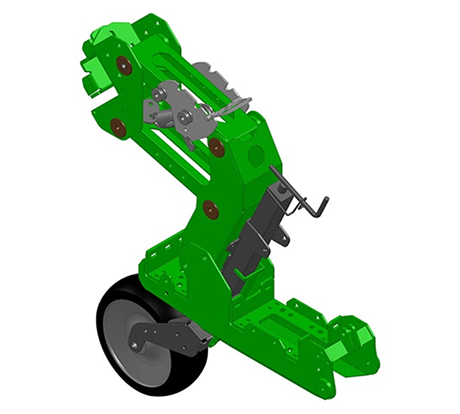

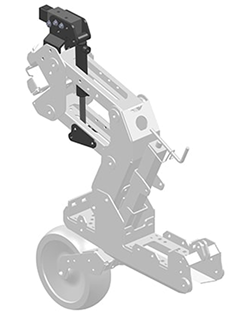

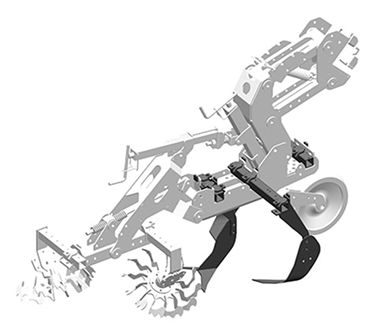

BASE ELEMENT

The cultivating element has been designed with reduced mechanical clearances, lightness and high rigidity to achieve maximum precision in the field.

Through the use of high-strength materials we have reduced weight and maintained robustness.

Each element is highly customizable to meet every requirement.

It is equipped with 300 mm diameter depth adjustment wheels, mounted on ball bearings with a crank for adjustment.

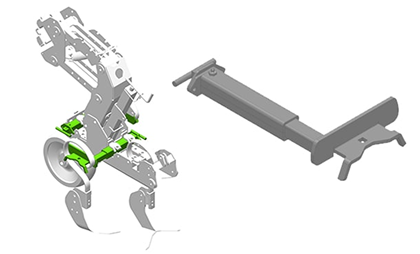

SPRINGS WITH DEPTH ADJUSTMENT

They can be mounted in place of spring supports and offer the possibility to adjust the height of the hoes.

ELEMENT LOAD CONTROL CYLINDER

A hydraulic cylinder can be mounted on each element to replace the spring.

The cylinder allows independent lifting of each element and enables adjustment of the downward thrust force by acting on the dedicated calibration valve.

INTER-ROW WHEELS

Patented wheels for working the soil between plants.

They are mounted on a rocker arm to adapt to the terrain and can be quickly adjusted in height with the handwheel adjustment.

Acting directly on the row, they break the crust, aerate the soil, uproot and eliminate weed germination, without damaging the crop.

For well-established crops, it is possible to increase the load for more aggressive action.

By varying the inclination, the wheel can ridge or leave the soil level. Three positions to cover every need.

ANTI-CLOGGING HOES ON RIGID SUPPORTS

Rigid and precise supports for working on light soils with few crop residues and weeds.

FIXED FRAME

Double fixed frame with width up to 3135 mm. The double frame allows positioning of elements in any position.

FERTILIZER DISTRIBUTOR

For sowing cover crops in the inter-row or for distributing microgranular fertilizer on the row.

ANTI-CLOGGING HOES ON SPRING

As standard, the machine is supplied with special anti-clogging hoes mounted on springs. These hoes cut the soil without moving clods, to achieve precision cultivation on surface layers.

Weeds are cut, the soil is not moved deeply and clods are not brought to the surface.

The springs are mounted on dedicated attachments that prevent lateral movement, to have the advantages of the spring with the precision of a rigid support.

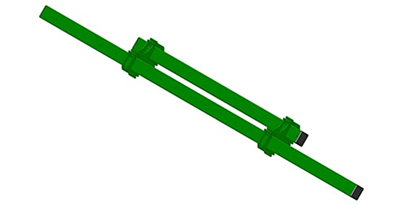

QUICK HOE ADJUSTMENT

Quick adjustment system for hoe width. It can be easily mounted in place of spring carrier tubes to quickly adjust the width of hoes or inter-row wheels.

In just seconds you can adjust the distance from plants without using tools.

FOLDING FRAME

Hydraulically foldable folding frame with width from 3780 to 6240 mm.

The transport width is 2500. The hinges are positioned under the frame to reduce the machine height during transport.

Customization and Support

Biotracker is configurable based on the farmer’s needs. Our technical team accompanies the customer in the selection and provides rapid support for maintenance, spare parts and future adaptations.